+8613251068920

+8613251068920Taizhou Xiongshi Plastic Mould Co., Ltd is a leading industrial mould manufacturer specializing in the design and production of durable crate moulds and high-efficiency turnover box moulds. If you need reliable plastic containers for logistics, storage, or material handling, our precision-engineered moulds are the foundation for your success.

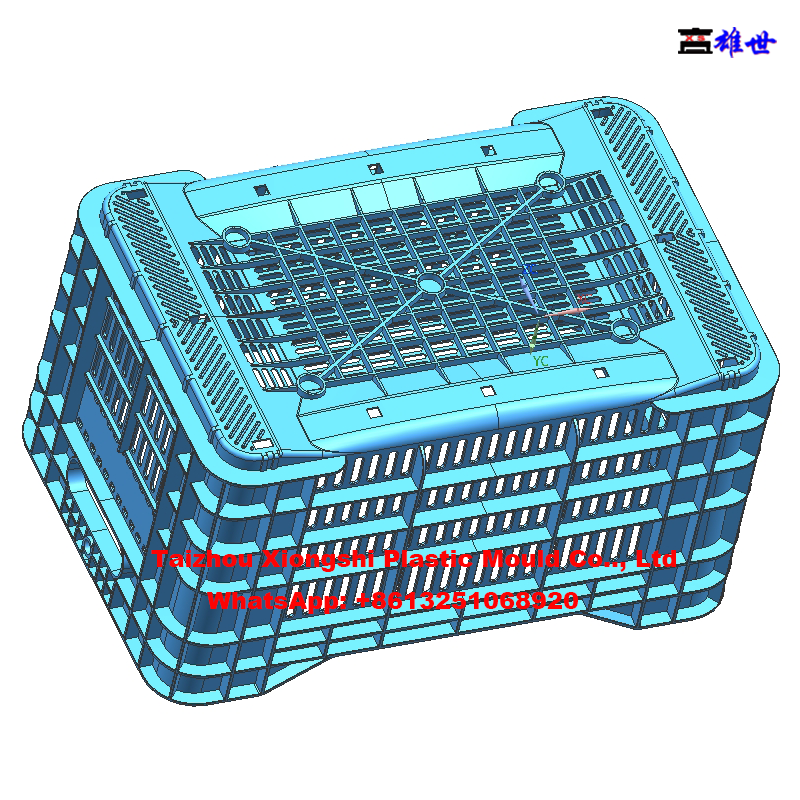

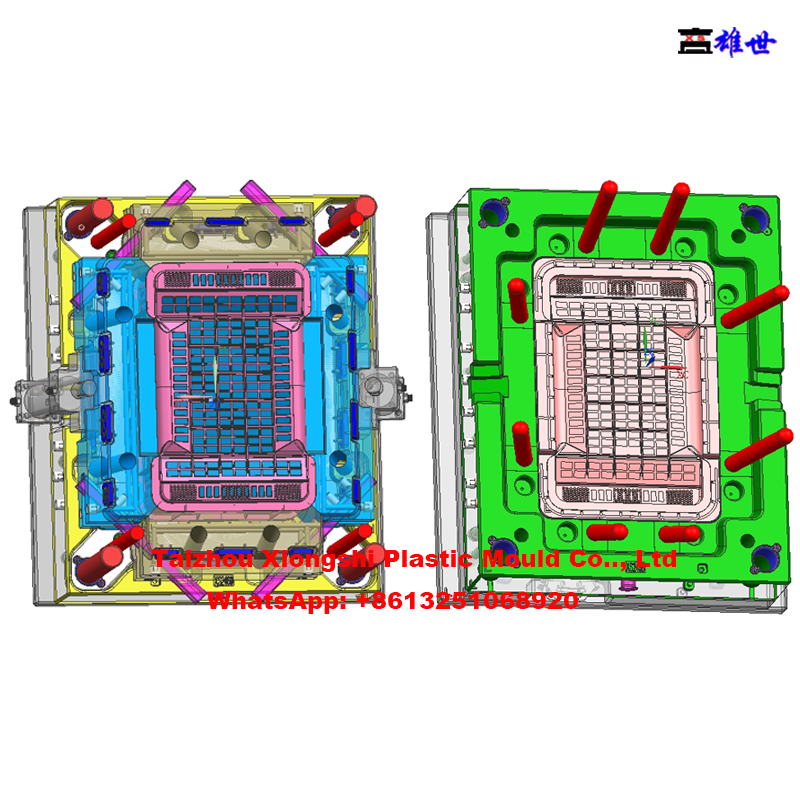

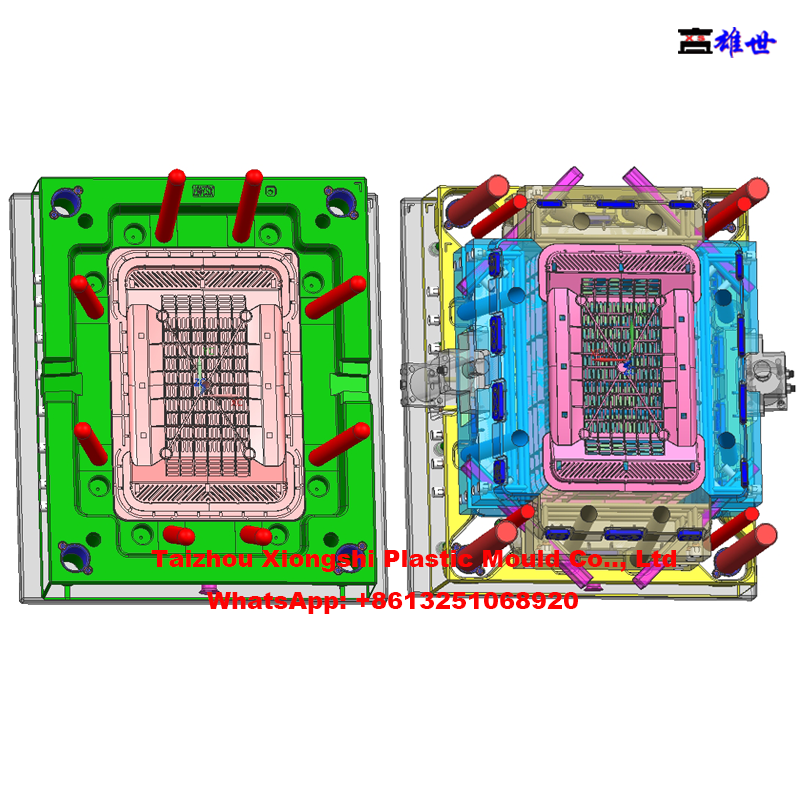

I. Crate Mould & Turnover Box Mould part 3D design.

3d design made according customer's sample. However some customers have design department who can provide the part design by themselves. Whatever our company design department can provide design change service. We can make little change which make the new product slight different with the original sample.

The original samples have little broken and deformation is no problem for us. Our engineer can analysis the samples and remove the deformations from the new design. Cooperating with our company is just like a breath of fresh spring air.

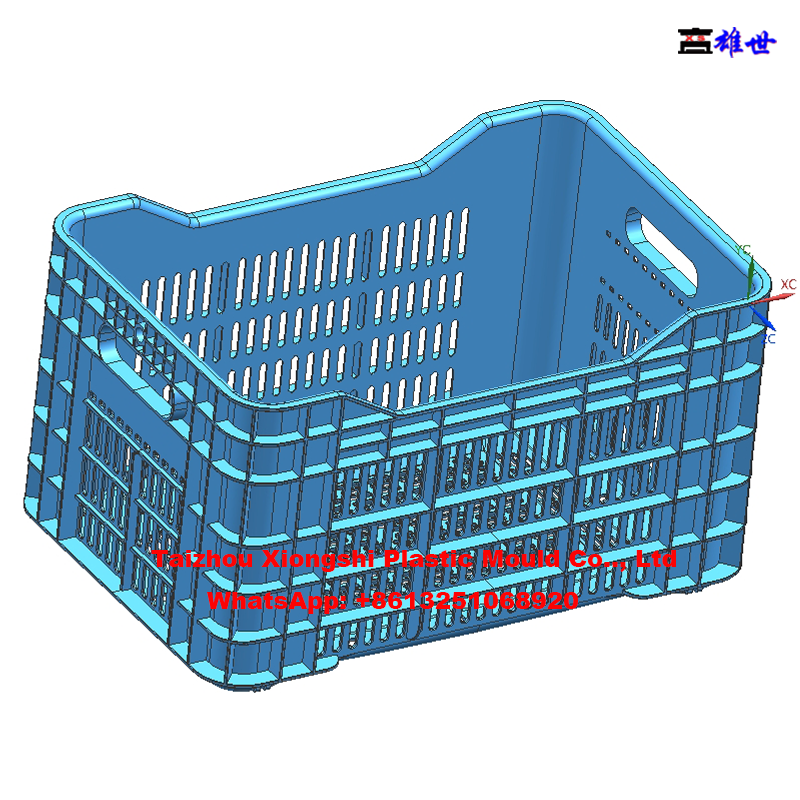

II. Crate Mould & Turnover Box Mould 3D design.

Our design department engineers all have rich experience in making crate moulds 3D design. The mould design hot runner system part need to be provided by hot runner supplier. Of course, we will check carefully, if there is problem, we will require the hot runner supplier to modify the mould hot runner system design.

During the moulds design stage, if customer can provide the injection machine specification will be helpfull for us to make the mould designs fit for customer's injection machine. Meanwhile tell us other requirement on the cooling fitting type, shot counter, limit switch, etc.

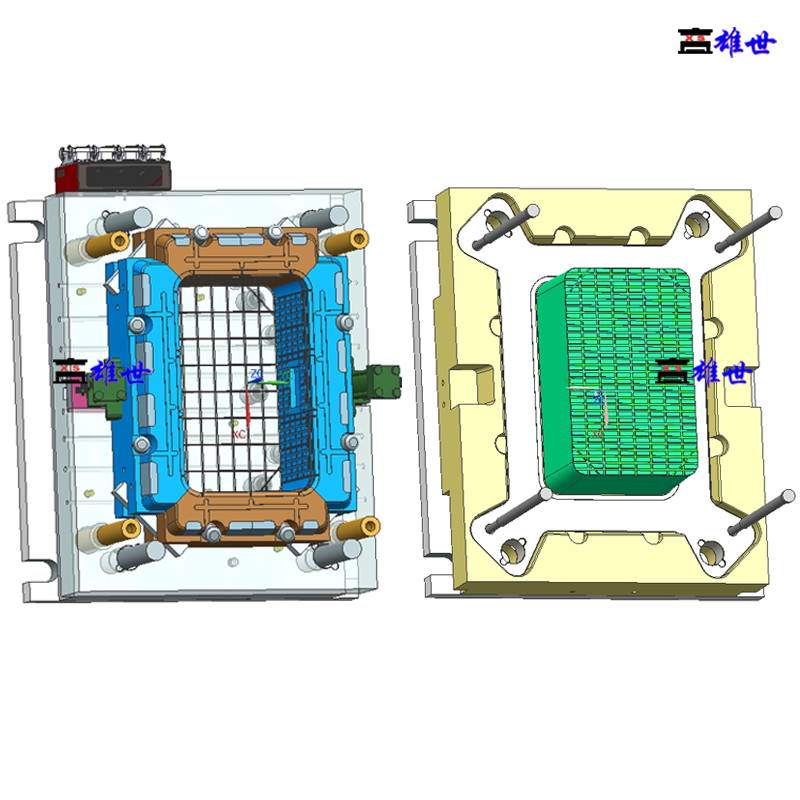

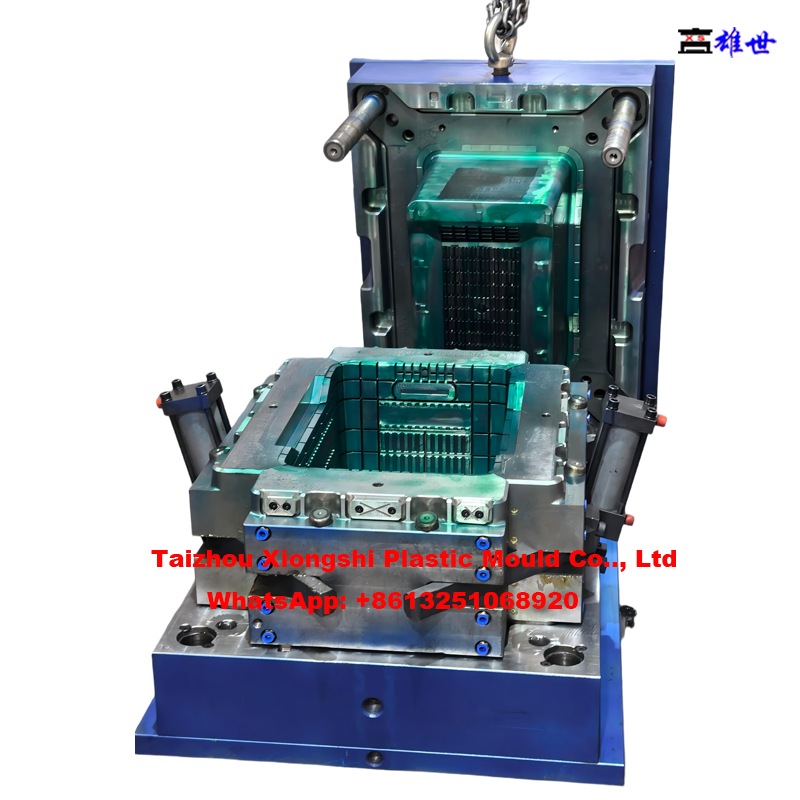

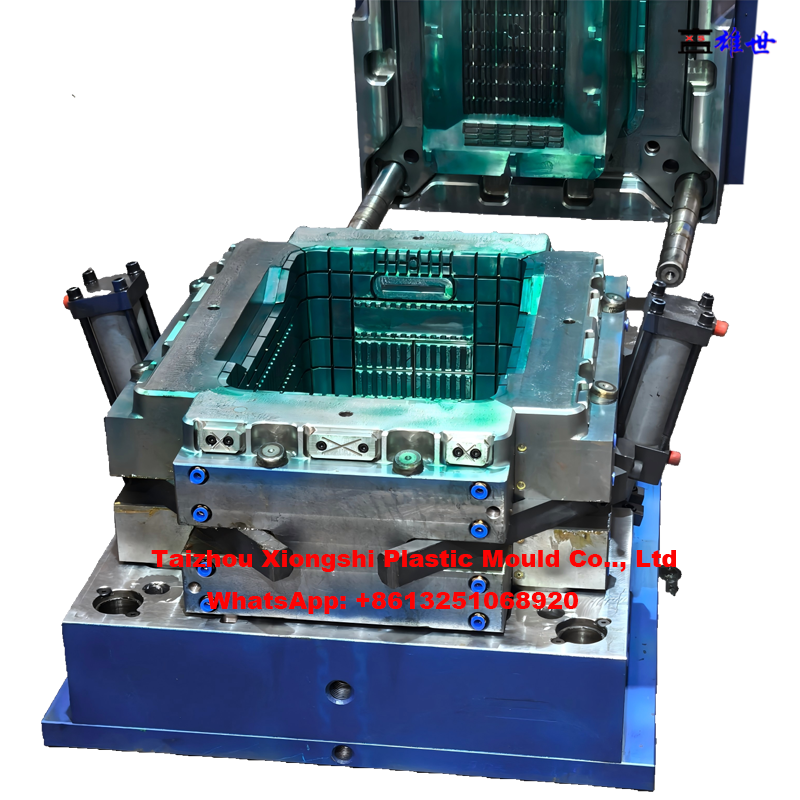

III. Crate Mould & Turnover Box Mould tooling process.

Steel plates cutting --> CNC milling tooling --> Hole Drilling --> EDW --> Deep Hole Drilling --> High Speed CNC milling tooling --> Mould Assembling --> Mould Polish --> Mould test.

IV. Crate Mould & Turnover Box Mould test.

Our company bear mould test cost, include the plastic raw material and injection machine fee. We provide customer 3-5pcs samples to inspect the quality.

V. Crate Mould & Turnover Box Mould test samples.

Mould test will be delivered to customer by express, or customer come to our factory to see the mould trail and inspect the mould and samples.

VI. Why Choose Our Moulds for Your Container Production?

We understand that your productivity depends on the quality and reliability of your moulds. That's why we build every crate and turnover box mould to the highest standards.

Superior Durability: Made from premium-grade steels (e.g., P20, 718, H13 Steel) for long-lasting performance and resistance to wear.

Maximum Efficiency: Optimized cooling systems and ejection mechanisms ensure fast cycle times, boosting your output.

Customization Available: We tailor every mould to your specific needs—size, weight capacity, stacking design, and logo imprint.

Expert Engineering: Decades of combined experience in injection mould design for industrial containers.

VII. Our Featured Mould Products

Our crate moulds are engineered to produce robust plastic crates capable of withstanding the toughest environments. Ideal for agriculture, warehousing, and automotive parts handling.

Applications: Logistics pallet boxes, produce crates, bottle crates, assembly line containers.

Key Features:

Reinforced walls and base for heavy loads.

Options for stackable and nestable designs to save space.

Smooth ejection and minimal maintenance downtime.

VIII. Efficient Turnover Box Moulds

Also known as nesting box moulds or stacking container moulds, our turnover box moulds are designed for optimal space utilization in logistics and assembly line processes. These boxes are the workhorses of modern intralogistics.

Applications: In-plant logistics, Kanban systems, assembly line parts supply, distribution centers.

Key Features:

Precision-engineered for easy nesting (when empty) and secure stacking (when full).

Ergonomic hand holes and easy-grip designs.

Compatible with automated conveyor systems.

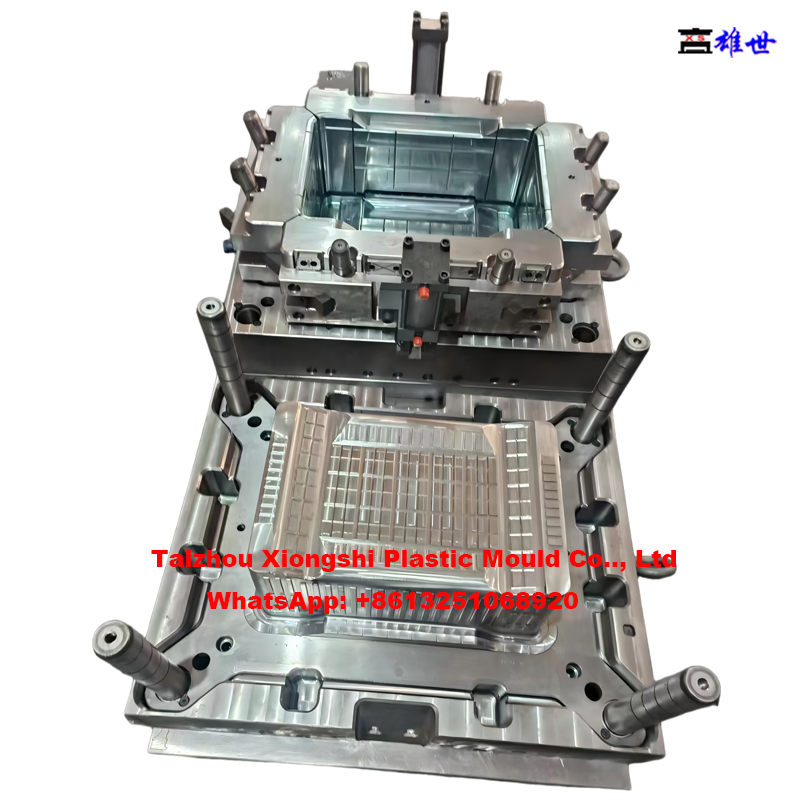

Ⅸ. Crate Mould & Turnover Box Mould pictures.

We leverage state-of-the-art technology to deliver moulds you can depend on.

Design: Advanced CAD/CAE software for simulation and optimization.

Machining: High-precision CNC milling, EDM, and deep-hole drilling.

Quality Control: Rigorous testing and inspection at every stage, from material to finished mould.

Service: Full project support from concept to mass production and after-sales service.

Logistics & Supply Chain

Agriculture & Horticulture

Automotive Manufacturing

Food & Beverage

General Manufacturing

Q1: What is the difference between a crate mould and a turnover box mould?

A: While both produce plastic containers, a crate mould typically creates a more rigid, heavy-duty box, often used for static storage or heavy item transport. A turnover box mould produces boxes designed for dynamic logistics, featuring designs that allow them to nest inside each other when empty to save space.

Q2: Can you customize the mould with our company logo?

A: Absolutely. We can easily incorporate your logo, part numbers, or any other text into the mould cavity for a clean, professional embossed or debossed finish on every container you produce.

Q3: What is the typical lead time for a custom crate mould?

A: Lead time depends on the mould's size and complexity. Generally, it ranges from 8 to 14 weeks. Contact us with your specifications for a precise timeline.

Q4: What plastic materials are commonly used with these moulds?

A: The most common materials are polypropylene (PP) and high-density polyethylene (HDPE) due to their excellent impact strength, durability, and chemical resistance.

Ready to enhance your container production with a high-quality, reliable mould? Our engineering team is here to help you develop the perfect solution.

Contact Us Now!

Or reach out directly:

Phone: +86 576 84407662

Email: sales@xsplasticmould.com

WhatsApp: +8613251068920

Screenshot, WeChat recognition QR code

WeChat account:+8613251068920

(Click WeChat to copy and add friends.)